ISO9001 Certified Professional Manufacturer & Supplier of Optics

+86-0431-87911611 admin@ytoptics.com

Contact us

-

Email: admin@ytoptics.com

Email: admin@ytoptics.com

-

Tel:86-0431-87911611

Tel:86-0431-87911611

-

Add: 2# Automotive Innovation

Add: 2# Automotive Innovation

Jilin Province, China

Changchun Yutai Optics Co., Ltd.

Principles and Applications of Visible High-Transmission Glass

In many cutting-edge optical systems, the most critical breakthroughs often stem from the most fundamental components. When system performance hits a bottleneck due to light loss or distortion, high-transmission glass in the visible spectrum becomes the decisive solution. It is not merely a “transparent” material, but a precision optical material that minimizes light absorption and reflection losses to the absolute limit within the human visible spectrum (380nm to 780nm), achieving near-total transmission. It represents a fundamental shift in optical design—from merely “allowing light to pass through” to “maximizing the preservation of light's energy and information.”

Fundamental Differences: Beyond Ordinary “Transparency”

The essential distinction between standard optical glass and professional high-transmission glass determines the performance ceiling of the entire system:

Efficiency Differences: Standard glass exhibits approximately 4% single-surface reflection loss. Even with conventional anti-reflective coatings, overall light transmission typically hovers around 95%. Professional high-transmission glass, however, employs extreme manufacturing techniques to reduce single-surface reflectance below 0.2%, achieving over 99.5% total light transmission. This seemingly minor percentage difference accumulates into significant optical energy loss in complex multi-lens systems.

Information Fidelity Difference: Ordinary glass cannot uniformly transmit all visible wavelengths, often causing color deviation. Residual reflected light generates disruptive stray light and ghosting within the system. High-transmission glass employs precise spectral control to ensure true color reproduction and significantly enhance imaging contrast.

Reliability Differences: While delivering ultimate optical performance, professional high-transmittance glass undergoes specialized strengthening processes. Its mechanical strength, surface hardness, and resistance to environmental aging far exceed standard products.

Core Principle: Dual Breakthroughs in Science and Craftsmanship

Achieving these distinctions relies on the deep integration of materials science and interface physics:

Ultra-Pure Bulk Materials: The foundation lies in creating an “optically pure” substrate. We employ specialized low-absorption formulations and vacuum melting techniques to control impurity ions like iron and copper to parts-per-billion levels, eliminating photon loss caused by impurity absorption at the source.

Interface Nanoengineering: The core lies in “managing light.” Using vacuum deposition technology, we deposit dozens of nanometer-thick dielectric films onto the glass surface. By precisely controlling the thickness and refractive index of each layer, we leverage the principle of destructive interference to actively cancel reflected light at specific wavelengths (visible light) at the interface. This “active anti-reflection” technology is key to achieving ultra-low reflectivity, broad spectral response, and wide-angle performance.

Application Areas

Precision Imaging and Sensing: Capturing faint signals is critical in semiconductor inspection equipment, high-end medical endoscopes, and space-to-ground observation systems. High-transmission glass maximizes the introduction of effective photons, directly enhancing system detection limits and imaging clarity.

Immersive Display (AR/VR/MR): Near-eye display devices demand extreme optical efficiency and ghosting control. As core optical components (e.g., waveguides, beam combiners), high-transmission glass significantly boosts image brightness and contrast while eliminating ghosting interference, forming the physical foundation for realistic immersive experiences.

High-Energy Laser Systems & Premium Lighting: In laser processing, laser displays, and specialized lighting equipment, thermal effects and energy loss in traditional optics cause overheating and lifespan issues. Ultra-low absorption in high-transmission glass is key to ensuring stable operation of high-power systems and improving energy efficiency.

Scientific & Analytical Instruments: Provides “interference-free” optical windows for high-resolution spectrometers, fluorescence detection systems, and similar equipment, guaranteeing absolute accuracy of measurement data.

Why Choose Us?

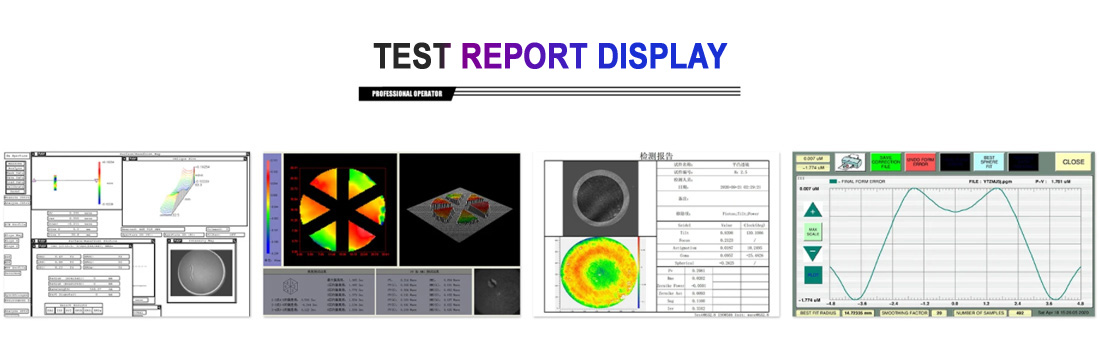

End-to-End Technical Control: From precision optical machining to customized coating, we maintain full in-house control throughout the process to ensure consistent quality.

Collaborative Design Capabilities: We optimize refractive index, Abbe number, and coating solutions based on your optical system architecture to achieve overall performance optimization.

Mass Production Consistency Assurance: Rigorous process control and inspection systems ensure every glass element meets design specifications with stable, reliable performance.

Selecting high-transmittance visible light glass means choosing a higher performance baseline and more reliable quality assurance for your optical systems. On the journey toward ultimate optical excellence, Yutai Optics is committed to being your most professional and dependable partner. With our profound understanding of light and masterful craftsmanship, we collaborate to push every performance boundary, turning clearer, truer, and more efficient optical experiences into reality.

Achieving these distinctions relies on the deep integration of materials science and interface physics:

Ultra-Pure Bulk Materials: The foundation lies in creating an “optically pure” substrate. We employ specialized low-absorption formulations and vacuum melting techniques to control impurity ions like iron and copper to parts-per-billion levels, eliminating photon loss caused by impurity absorption at the source.

Interface Nanoengineering: The core lies in “managing light.” Using vacuum deposition technology, we deposit dozens of nanometer-thick dielectric films onto the glass surface. By precisely controlling the thickness and refractive index of each layer, we leverage the principle of destructive interference to actively cancel reflected light at specific wavelengths (visible light) at the interface. This “active anti-reflection” technology is key to achieving ultra-low reflectivity, broad spectral response, and wide-angle performance.

Application Areas

Precision Imaging and Sensing: Capturing faint signals is critical in semiconductor inspection equipment, high-end medical endoscopes, and space-to-ground observation systems. High-transmission glass maximizes the introduction of effective photons, directly enhancing system detection limits and imaging clarity.

Immersive Display (AR/VR/MR): Near-eye display devices demand extreme optical efficiency and ghosting control. As core optical components (e.g., waveguides, beam combiners), high-transmission glass significantly boosts image brightness and contrast while eliminating ghosting interference, forming the physical foundation for realistic immersive experiences.

High-Energy Laser Systems & Premium Lighting: In laser processing, laser displays, and specialized lighting equipment, thermal effects and energy loss in traditional optics cause overheating and lifespan issues. Ultra-low absorption in high-transmission glass is key to ensuring stable operation of high-power systems and improving energy efficiency.

Scientific & Analytical Instruments: Provides “interference-free” optical windows for high-resolution spectrometers, fluorescence detection systems, and similar equipment, guaranteeing absolute accuracy of measurement data.

Why Choose Us?

End-to-End Technical Control: From precision optical machining to customized coating, we maintain full in-house control throughout the process to ensure consistent quality.

Collaborative Design Capabilities: We optimize refractive index, Abbe number, and coating solutions based on your optical system architecture to achieve overall performance optimization.

Mass Production Consistency Assurance: Rigorous process control and inspection systems ensure every glass element meets design specifications with stable, reliable performance.

Selecting high-transmittance visible light glass means choosing a higher performance baseline and more reliable quality assurance for your optical systems. On the journey toward ultimate optical excellence, Yutai Optics is committed to being your most professional and dependable partner. With our profound understanding of light and masterful craftsmanship, we collaborate to push every performance boundary, turning clearer, truer, and more efficient optical experiences into reality.

PREV : Why choose broadband anti-reflective coating(BBAR)? NEXT : How to mount a dome housing to an underwater camera ?

TALK TO US 86-0431-87911611

86-0431-87911611

Call us now!

86-0431-87911611

86-0431-87911611Call us now!

ONLINE CHAT

2433808388

2433808388