ISO9001 Certified Professional Manufacturer & Supplier of Optics

+86-0431-87911611 admin@ytoptics.com

Contact us

-

Email: admin@ytoptics.com

Email: admin@ytoptics.com

-

Tel:86-0431-87911611

Tel:86-0431-87911611

-

Add: 2# Automotive Innovation

Add: 2# Automotive Innovation

Jilin Province, China

Changchun Yutai Optics Co., Ltd.

Home > Products > Prisms > Equilateral Prisms

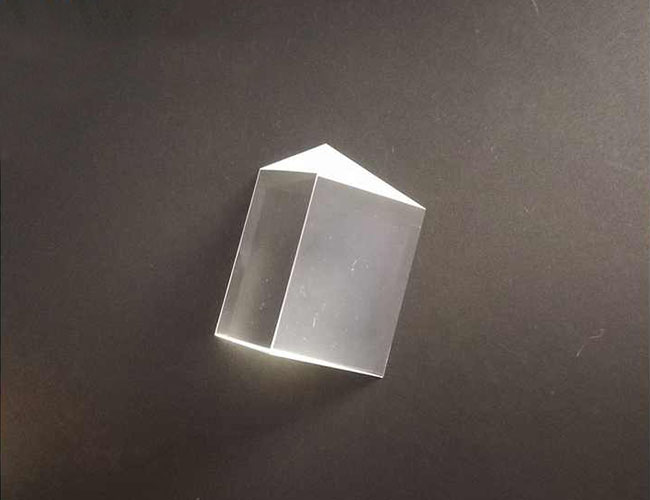

BK7 Optical Glass Equilateral Prism

An equilateral prism usually refers to an optical prism with an equilateral triangular cross-section, also known as an Equilateral Triangular Prism. These prisms are widely used in optical experiments and instruments.

Share this:

What are the advantages of BK7 (K9) equilateral prisms?

1. Cost-effective

Low cost: BK7 is a common optical glass, the raw material and processing cost is much lower than fused silica, suitable for projects with limited budget.

Easy to process: BK7 has moderate hardness (Mohs hardness 6-7) and is easy to cut, polish and coat, making it suitable for mass production.

2. Excellent optical transmittance

Outstanding performance in visible wavelength: high transmittance in the range of 350nm-2000nm (especially >90% in 400nm-1000nm), suitable for visible and near infrared applications (e.g. cameras, microscopes, laser systems).

Low bubbles and impurities: BK7 glass has high purity and few internal defects, reducing light scattering and energy loss.

3. Low dispersion (medium Abbe number)

Abbe number about 64.2: dispersion is lower than ordinary glass, but higher than fused silica (Abbe number 67), suitable for medium precision optical systems (e.g., imaging lenses, telescopes) that need to control chromatic aberration.

4. Stable mechanical and chemical properties

Environmental resistance: resistant to humidity and slight acid and alkali corrosion, suitable for laboratory or industrial environments.

Moderate coefficient of thermal expansion (7.1×10-⁶/°C): not as stable as fused silica, but reliable performance in the conventional temperature range (-30°C~70°C).

How do I choose the material for an equilateral prism?

BK7: general purpose optical systems, low cost experiments, imaging applications.

SF11: scenarios requiring strong dispersion or high refractive index (e.g. spectrometers).

Fused silica: UV wavelength or high laser damage threshold needs.

1. Cost-effective

Low cost: BK7 is a common optical glass, the raw material and processing cost is much lower than fused silica, suitable for projects with limited budget.

Easy to process: BK7 has moderate hardness (Mohs hardness 6-7) and is easy to cut, polish and coat, making it suitable for mass production.

2. Excellent optical transmittance

Outstanding performance in visible wavelength: high transmittance in the range of 350nm-2000nm (especially >90% in 400nm-1000nm), suitable for visible and near infrared applications (e.g. cameras, microscopes, laser systems).

Low bubbles and impurities: BK7 glass has high purity and few internal defects, reducing light scattering and energy loss.

3. Low dispersion (medium Abbe number)

Abbe number about 64.2: dispersion is lower than ordinary glass, but higher than fused silica (Abbe number 67), suitable for medium precision optical systems (e.g., imaging lenses, telescopes) that need to control chromatic aberration.

4. Stable mechanical and chemical properties

Environmental resistance: resistant to humidity and slight acid and alkali corrosion, suitable for laboratory or industrial environments.

Moderate coefficient of thermal expansion (7.1×10-⁶/°C): not as stable as fused silica, but reliable performance in the conventional temperature range (-30°C~70°C).

How do I choose the material for an equilateral prism?

BK7: general purpose optical systems, low cost experiments, imaging applications.

SF11: scenarios requiring strong dispersion or high refractive index (e.g. spectrometers).

Fused silica: UV wavelength or high laser damage threshold needs.

TALK TO US 86-0431-87911611

86-0431-87911611

Call us now!

86-0431-87911611

86-0431-87911611Call us now!

ONLINE CHAT

2433808388

2433808388