ISO9001 Certified Professional Manufacturer & Supplier of Optics

+86-0431-87911611 admin@ytoptics.com

Contact us

-

Email: admin@ytoptics.com

Email: admin@ytoptics.com

-

Tel:86-0431-87911611

Tel:86-0431-87911611

-

Add: 2# Automotive Innovation

Add: 2# Automotive Innovation

Jilin Province, China

Changchun Yutai Optics Co., Ltd.

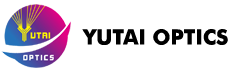

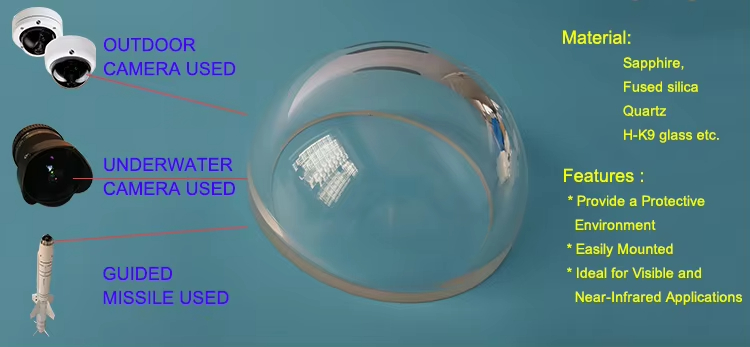

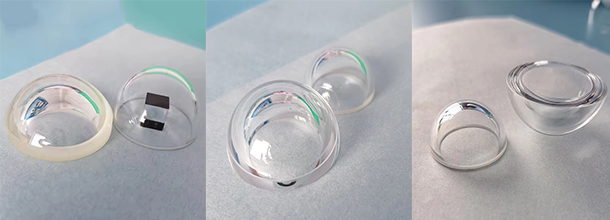

Yutai Optics 一Optical Domes

Basic Concept and Function

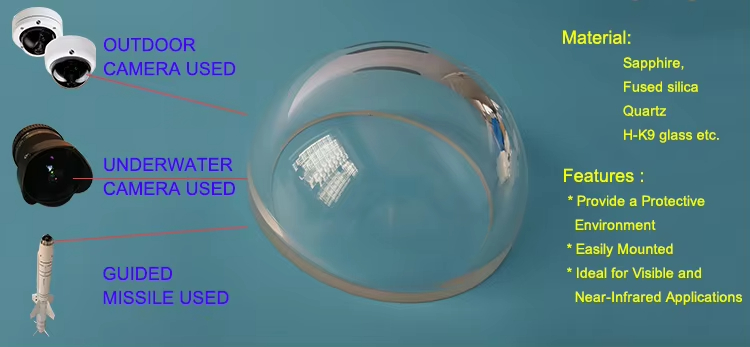

An optical dome is a hemispherical or hyper-hemispherical optical component widely used in various optoelectronic systems. Its primary function is to protect internal precision optical components from external environmental factors (such as dust, rain, and sand) while maintaining the imaging performance of the optical system. Typically installed as the outermost layer of optoelectronic devices, the dome serves as the first optical interface, and its quality directly affects the imaging performance of the entire system.

Material Selection and Properties

The choice of dome material is critical. Common materials include optical glass (BK7, fused silica), sapphire, and infrared materials (ZnSe, Ge). Key considerations for material selection include:

Optical Performance: Transmission rate, refractive index uniformity, and birefringence.

Mechanical Strength: Impact resistance, flexural strength, and other mechanical properties.

Environmental Stability: Temperature resistance, corrosion resistance, and anti-aging performance.

Manufacturability: Ease of processing into high-precision spherical surfaces.

Sapphire domes are widely used in high-end military and aerospace applications due to their exceptional hardness (Mohs 9) and broad-spectrum transmission properties, though they come at a higher cost.

Key Design and Manufacturing Technologies

Optical Design: Domes introduce aberrations, particularly spherical and chromatic aberrations, which must be optimized using optical design software. Hyper-hemispherical designs can expand the field of view but exacerbate aberration issues.

Coating Technology:

Anti-reflective coatings: Reduce surface reflections and improve transmittance.

Hydrophobic coatings: Enhance water repellency.

Anti-static coatings: Prevent dust accumulation.

Special dichroic coatings may be required for infrared applications.

Manufacturing Processes:

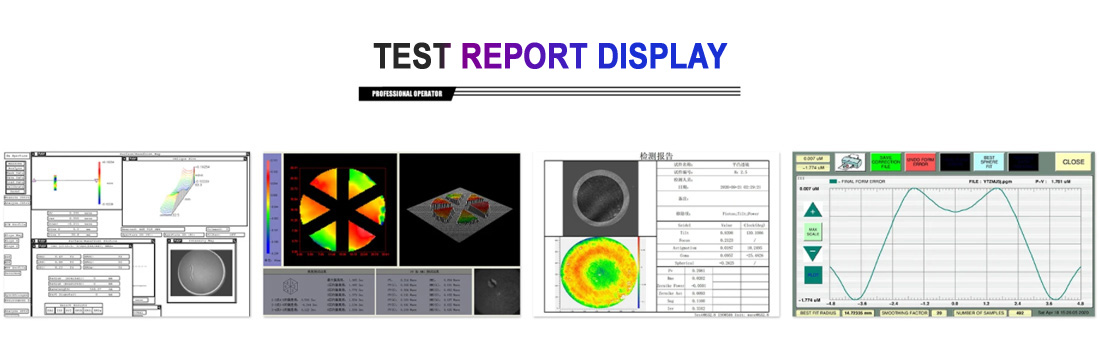

High-precision spherical surface machining (typically requiring surface accuracy better than λ/4).

Edge treatment techniques.

Surface roughness control (usually <5 nm).

Typical Application Fields

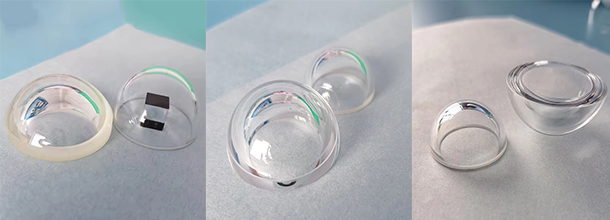

Underwater Optical Systems: Used in underwater cameras and remotely operated vehicles (ROVs), requiring high-pressure resistance and corrosion protection.

Aerospace: Missile seekers, airborne electro-optical pods, etc., demanding high-temperature resistance and impact durability.

Security Surveillance: All-weather dome cameras requiring wide-spectrum transmission and self-cleaning functions.

Industrial Inspection: Protective covers for optical inspection equipment in harsh environments.

Future Development Trends

With advancements in optoelectronic technology, dome technology is evolving in the following directions:

Multi-functional composite coatings.

Lightweight designs (thin-walled domes).

Smart domes (integrated sensors, self-healing capabilities).

Applications of new materials (transparent ceramics, nanocomposites).

As a critical component of optoelectronic systems, optical domes play a vital role in improving system reliability. With continued progress in manufacturing techniques and material science, dome technology will continue to advance, meeting increasingly demanding application requirements.

Yutai Optics provides domes from glass, quartz, depending on the temperature, shock and scratch resistance required. These items will be manufactured on customer request only.

An optical dome is a hemispherical or hyper-hemispherical optical component widely used in various optoelectronic systems. Its primary function is to protect internal precision optical components from external environmental factors (such as dust, rain, and sand) while maintaining the imaging performance of the optical system. Typically installed as the outermost layer of optoelectronic devices, the dome serves as the first optical interface, and its quality directly affects the imaging performance of the entire system.

Material Selection and Properties

The choice of dome material is critical. Common materials include optical glass (BK7, fused silica), sapphire, and infrared materials (ZnSe, Ge). Key considerations for material selection include:

Optical Performance: Transmission rate, refractive index uniformity, and birefringence.

Mechanical Strength: Impact resistance, flexural strength, and other mechanical properties.

Environmental Stability: Temperature resistance, corrosion resistance, and anti-aging performance.

Manufacturability: Ease of processing into high-precision spherical surfaces.

Sapphire domes are widely used in high-end military and aerospace applications due to their exceptional hardness (Mohs 9) and broad-spectrum transmission properties, though they come at a higher cost.

Key Design and Manufacturing Technologies

Optical Design: Domes introduce aberrations, particularly spherical and chromatic aberrations, which must be optimized using optical design software. Hyper-hemispherical designs can expand the field of view but exacerbate aberration issues.

Coating Technology:

Anti-reflective coatings: Reduce surface reflections and improve transmittance.

Hydrophobic coatings: Enhance water repellency.

Anti-static coatings: Prevent dust accumulation.

Special dichroic coatings may be required for infrared applications.

Manufacturing Processes:

High-precision spherical surface machining (typically requiring surface accuracy better than λ/4).

Edge treatment techniques.

Surface roughness control (usually <5 nm).

Typical Application Fields

Underwater Optical Systems: Used in underwater cameras and remotely operated vehicles (ROVs), requiring high-pressure resistance and corrosion protection.

Aerospace: Missile seekers, airborne electro-optical pods, etc., demanding high-temperature resistance and impact durability.

Security Surveillance: All-weather dome cameras requiring wide-spectrum transmission and self-cleaning functions.

Industrial Inspection: Protective covers for optical inspection equipment in harsh environments.

Future Development Trends

With advancements in optoelectronic technology, dome technology is evolving in the following directions:

Multi-functional composite coatings.

Lightweight designs (thin-walled domes).

Smart domes (integrated sensors, self-healing capabilities).

Applications of new materials (transparent ceramics, nanocomposites).

As a critical component of optoelectronic systems, optical domes play a vital role in improving system reliability. With continued progress in manufacturing techniques and material science, dome technology will continue to advance, meeting increasingly demanding application requirements.

Yutai Optics provides domes from glass, quartz, depending on the temperature, shock and scratch resistance required. These items will be manufactured on customer request only.

PREV : What is the achromatic doublet lens ? NEXT : Technical Principles and Application Prospects of Infrared Filters

TALK TO US 86-0431-87911611

86-0431-87911611

Call us now!

86-0431-87911611

86-0431-87911611Call us now!

ONLINE CHAT

2433808388

2433808388