ISO9001 Certified Professional Manufacturer & Supplier of Optics

+86-0431-87911611 admin@ytoptics.com

Contact us

-

Email: admin@ytoptics.com

Email: admin@ytoptics.com

-

Tel:86-0431-87911611

Tel:86-0431-87911611

-

Add: 2# Automotive Innovation

Add: 2# Automotive Innovation

Jilin Province, China

Changchun Yutai Optics Co., Ltd.

AR coating & IR coating

In the field of optical technology, AR coating and IR coating represent two critical types of technology. While their names are similar, their core functions and application logic are fundamentally different.

AR Coating: Enhancing Light Transmission, Eliminating Interference

The core objective of AR coating is to increase the transmission rate of visible light. It utilizes the principle of light interference by depositing multiple thin films onto the lens surface, causing reflections from the upper and lower surfaces of the film to cancel each other out. This reduces the surface reflectance of ordinary glass from approximately 4% to below 1%.

Its primary effects include:

Clearer Vision: Significantly reduces glare and reflections while boosting light transmission.

More Accurate Imaging: Improves contrast and color fidelity in images.

Enhanced Aesthetics: Often exhibits green or purple surface reflections.

AR coating is widely used in eyeglass lenses, camera lenses, and high-end displays, serving as an “enhanced performance” technology.

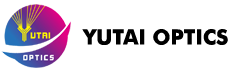

IR Coating: Precise Filtering for Accuracy

The core objective of IR coating is to selectively block infrared light. It functions like a “spectral filter,” allowing only visible light to pass through while reflecting or absorbing infrared rays (especially near-infrared) invisible to the human eye.

Its fundamental purpose stems from the sensitivity of modern CMOS/CCD image sensors to infrared light. Without interception, infrared radiation causes reddish tints, blurring, and loss of focus in images.

Consequently, IR coating is an essential component in imaging modules for all digital cameras, smartphone cameras, and security cameras, functioning as a corrective technology to address these issues.

In modern precision optical systems, the two often work in tandem: each lens is coated with an AR coating to minimize light loss, while an IR cutoff filter is placed in front of the sensor to purify the light. More advanced composite coating technologies can even integrate both functions into a single layer.

In summary, AR coating focuses on “letting the light that should pass through better pass,” addressing surface reflection issues; IR coating handles “preventing the light that shouldn't pass through from doing so,” tackling spectral interference problems. Together, this ‘permeation’ and “blocking” lay the foundation for clear, accurate imaging.

AR Coating: Enhancing Light Transmission, Eliminating Interference

The core objective of AR coating is to increase the transmission rate of visible light. It utilizes the principle of light interference by depositing multiple thin films onto the lens surface, causing reflections from the upper and lower surfaces of the film to cancel each other out. This reduces the surface reflectance of ordinary glass from approximately 4% to below 1%.

Its primary effects include:

Clearer Vision: Significantly reduces glare and reflections while boosting light transmission.

More Accurate Imaging: Improves contrast and color fidelity in images.

Enhanced Aesthetics: Often exhibits green or purple surface reflections.

AR coating is widely used in eyeglass lenses, camera lenses, and high-end displays, serving as an “enhanced performance” technology.

IR Coating: Precise Filtering for Accuracy

The core objective of IR coating is to selectively block infrared light. It functions like a “spectral filter,” allowing only visible light to pass through while reflecting or absorbing infrared rays (especially near-infrared) invisible to the human eye.

Its fundamental purpose stems from the sensitivity of modern CMOS/CCD image sensors to infrared light. Without interception, infrared radiation causes reddish tints, blurring, and loss of focus in images.

Consequently, IR coating is an essential component in imaging modules for all digital cameras, smartphone cameras, and security cameras, functioning as a corrective technology to address these issues.

In modern precision optical systems, the two often work in tandem: each lens is coated with an AR coating to minimize light loss, while an IR cutoff filter is placed in front of the sensor to purify the light. More advanced composite coating technologies can even integrate both functions into a single layer.

In summary, AR coating focuses on “letting the light that should pass through better pass,” addressing surface reflection issues; IR coating handles “preventing the light that shouldn't pass through from doing so,” tackling spectral interference problems. Together, this ‘permeation’ and “blocking” lay the foundation for clear, accurate imaging.

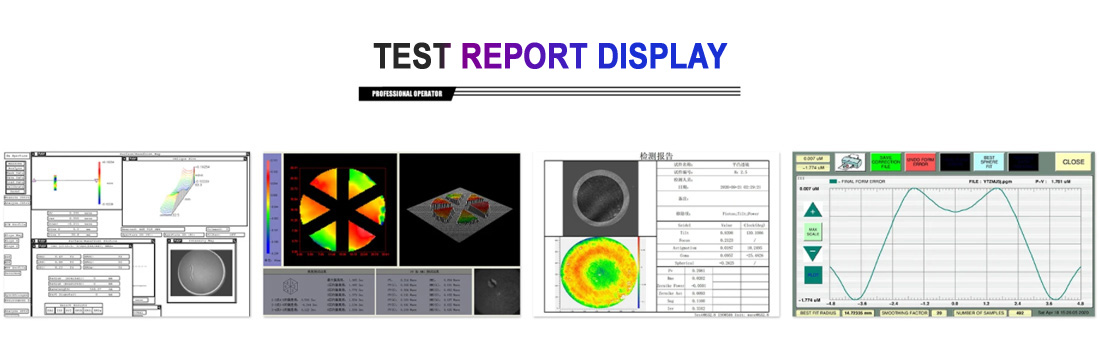

PREV : Optical Lens Inspection Methods NEXT : Basics of Optical Spherical Lens Processing

TALK TO US 86-0431-87911611

86-0431-87911611

Call us now!

86-0431-87911611

86-0431-87911611Call us now!

ONLINE CHAT

2433808388

2433808388