ISO9001 Certified Professional Manufacturer & Supplier of Optics

+86-0431-87911611 admin@ytoptics.com

Contact us

-

Email: admin@ytoptics.com

Email: admin@ytoptics.com

-

Tel:86-0431-87911611

Tel:86-0431-87911611

-

Add: 2# Automotive Innovation

Add: 2# Automotive Innovation

Jilin Province, China

Changchun Yutai Optics Co., Ltd.

K9 Glass : Classic Materials in Optical Components

◆The composition of K9 is as follows: SiO2=69.13%, B2O3=10.75%, BaO=3.07%, Na2O=10.40%, K2O=6.29%, As2O3=0.36%

◆The optical constants of K9 are as follows: Refractive index=1.51630, Dispersion=0.00806, Abbe number=64.06

◆The national standard of optical glass is classified according to Abbe number. The glass with Abbe number ≥50 is coronal glass, which is expressed by "K"; the glass with Abbe number <50 is flint glass, which is expressed by "F". Under these two categories, light "Q", heavy "Z", special "T" and chemical element symbols plus prefixes, numbers plus suffixes for subdivision, divided into 18 categories, 141 grades. For example: QF8 (light flint), BaK11 (barium corona), K9 (corona).

◆ Generally, the corona brand belongs to the alkali silicate system, and the vast majority of flint glass belongs to the lead silicate system.

Optical Properties and Advantages

K9 glass features a uniform refractive index distribution and moderate dispersion, effectively reducing chromatic aberration and enhancing imaging quality. Its high hardness (Mohs hardness 5.5) and chemical stability enable it to resist environmental corrosion, extending component lifespan. Additionally, K9 glass offers low cost and suitability for mass production, making it widely used in optical instruments such as microscopes, telescopes, and camera lenses.

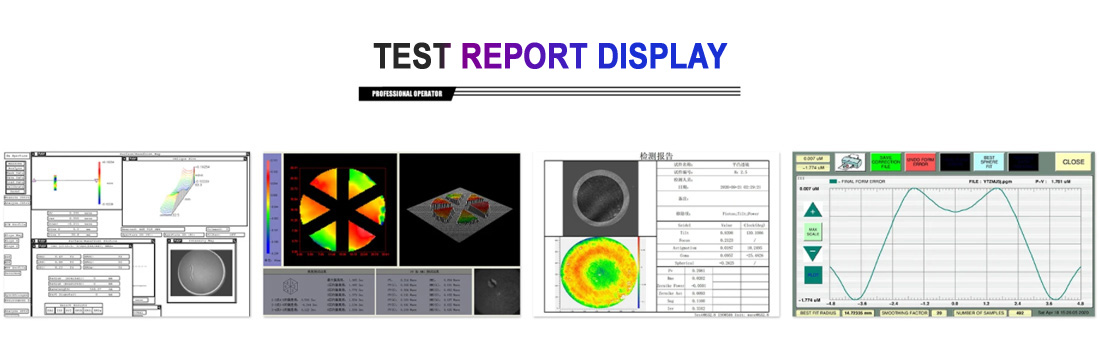

Precision Manufacturing Process

Manufacturing K9 optical components involves precision processes such as cutting, grinding, and polishing. High-precision machining ensures surface roughness at the nanometer level, reducing light scattering and enhancing transmittance. Coating technologies further optimize performance—anti-reflective coatings boost light transmission, while protective coatings improve wear resistance.

Application Scenarios

K9 glass is indispensable in scientific research, medical, and industrial fields. For instance, microscope objectives and eyepieces utilize K9 lenses to ensure high-resolution imaging, while optical components in laser systems rely on its stability. With technological advancements, K9 glass demonstrates potential in infrared optics and radiation-resistant applications, adapting to complex environmental demands.

PREV : Filter NEXT : Filter for microplate reader

TALK TO US 86-0431-87911611

86-0431-87911611

Call us now!

86-0431-87911611

86-0431-87911611Call us now!

ONLINE CHAT

2433808388

2433808388